In the world of power tools, there are countless options to choose from. But when it comes to drilling and driving tasks, two heavyweights stand out: the hammer drill and the impact driver. These tools share some similarities, but they also have distinct differences that make them better suited for certain jobs. In this article, we'll take a closer look at the hammer drill vs impact driver showdown and help you determine which one is right for your needs.

If you're new to the world of power tools, you might be wondering what sets these two tools apart. Both the hammer drill and impact driver are designed to drill holes and drive screws, but they do so in different ways. A hammer drill uses a pounding motion to break through tougher materials like concrete or masonry. An impact driver, on the other hand, uses rotational force (or torque) to drive screws quickly and efficiently. While there is some overlap in their capabilities, each tool has its own strengths and weaknesses that make it better suited for certain tasks. So which one should you choose? Let's find out!

Related reading: Best Diy Painting Tools

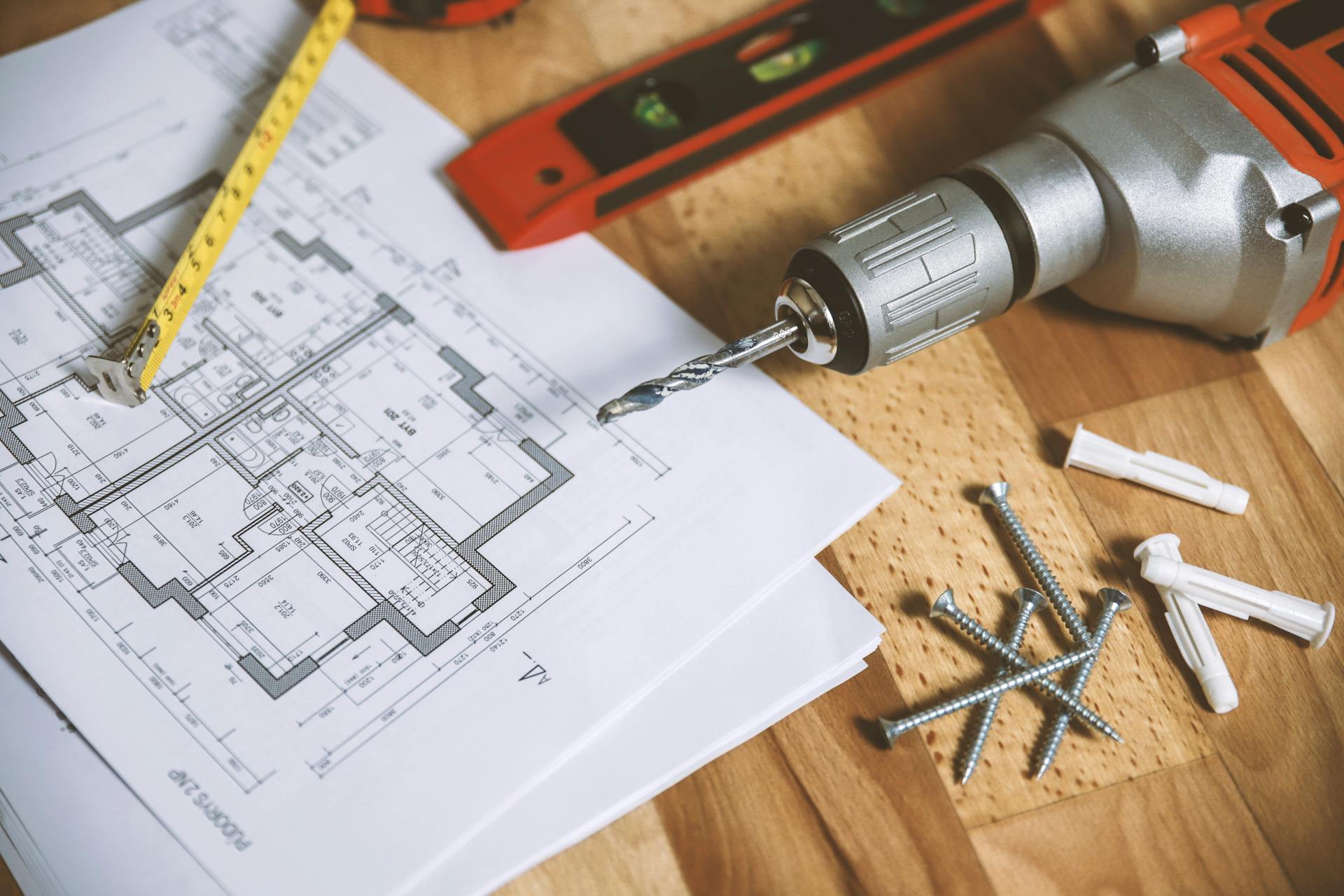

As a DIYer, have you wondered about whether to use or rent a hammer drill vs an impact driver? Here we explain how to easily make that decision.

Hammer drills and impact drivers are frequently confused tools. As a DIYer, it's important to know the difference between them, so you can choose the right tool for the job. Experts handpick these two power tools as essential additions to any DIYer’s toolbox.

Hammer drills have a loud feature that uses a striking mechanism to drill through hard materials like concrete or brick. They're perfect for heavy-duty jobs that require drilling into tough surfaces. On the other hand, impact drivers drive fasteners with ease and speed due to their specific strengths in torque output and driving power.

So, as a DIYer, how do you decide whether to use or rent a hammer drill vs an impact driver? If your project involves drilling holes in tough surfaces like concrete or brick, then you need a hammer drill. However, if you want to drive screws more efficiently and quickly without the need for pre-drilling holes, then an impact driver is your best bet. Understanding these key differences will help you make an informed decision when choosing between these two powerful tools.

Discover the Power of a Hammer Drill

Hammer drills are a type of power drill that is designed to bore holes through tough surfaces. Unlike traditional power drills, hammer drills have an additional hammer setting and mechanism inside that delivers hammer strikes aka blows to send the drill bit forward. This action punches through concrete, stone, brick, and other hard materials with ease.

When compared to standard power drills, hammer drills offer more speed controls and are generally speaking larger in size. They also have standard chucks triggers like a regular drill but can deliver up to 48,000 blows per minute (bpm). As a result, they are ideal for heavy-duty projects such as drilling into concrete or masonry.

Modern advancements in lithium-ion technology mean that battery-operated models of hammer drills are now available. However, corded models still offer more power and don't require recharging. Generally speaking, hammer drills cost more than impact drivers but they're worth the investment if you need to work on tough surfaces.

A unique perspective: Drill Bits

How Different Types of Drills Work: A Closer Look

Hammer drills and impact drivers are both tools used for drilling, but they work in different ways. Hammer drills use a forward thrusting motion combined with a rotational force to drill through tough materials like concrete and brick. They typically have a special setting that activates the hammering mechanism, allowing the drill bit to break through the surface. Impact drivers, on the other hand, use a combination of high torque and rapid bursts of force to drive screws and bolts into place. They are not designed for drilling holes with drill bits, but rather for driving fasteners into wood or metal.

1. Each has a different chuck and accepts different bits.

Each tool has a different chuck and accepts different bits. Hammer drills come with either a keyed or keyless chuck, while impact drivers invariably have a quick-release clamp designed to secure hex-shank driver and drill bits. The self-centering three-jaw chuck on heavy-duty models provides a tighter grip on round-shank drill bits, while SDS hammer drills use an SDS chuck that comes in several sizes to accommodate various SDS drill bits. The spring-loaded chuck is equipped with ball bearings that allow it to slide back and forth as the bit moves up and down, while the sliding sleeve releases its grip when you want to remove a bit.

When it comes to drilling through masonry, base material high-speed steel (HSS) or general-purpose masonry bits won't cut it - you need more specialized tools like spiral-fluted masonry bits with carbide tips or SDS drill bits. Masonry bits differ from standard drill bits in their shape and design: they feature wide flutes that funnel waste material out of the hole as you're drilling and have a flat tip that won't skid off the surface. If you're doing occasional drilling duties or driving screws into wood, metal, or plastic fasteners straight Philips or square-drive driving bits are sufficient for the job. However, if you need additional force to loosen stubborn bolts or nuts or drive long screws into dense materials like hardwoods or thick metal sheets, an impact driver might be your best bet.

Discover the Mighty Tool: Impact Driver

The impact driver is a powerful tool that can drive fasteners and lag bolts with ease. Unlike typical drills, impact drivers feature quick-change ball-bearing chucks or special chucks that utilize standard drill bits with round shanks; they're compatible with hex-shank quick-change impact-ready driver bits too. Impact drivers are typically shorter than standard drills, but they make up for it by spinning fasteners clockwise at high speeds.

When you use an impact driver, you'll notice how different it feels compared to a standard drill. The rotational impact anvil strikes the back of the bit as it spins, giving you additional torque and allowing you to drive longer and bigger fasteners. Impact drivers speed up your work by ensuring that tools don't rotate in a steady constant direction but rather move the bit forward while quickly twisting it backward — this helps prevent the driver bit from slipping, resulting in fewer stripped fasteners.

Cordless impact drivers generally cost more than cordless drills because they come with additional torque and power. Some models even have settings where the tool automatically activates a few thousand times per minute (IPM) to achieve 4000 impacts per minute (IPM), making them ideal for those who need to drive screws into dense materials like hardwoods or masonry. If you're someone who constantly works with tough materials, then investing in an impact driver will be worth every penny.

Drilling holes and driving screws through any material is easy—as long as you have the right tools for the job. Find out whether you’d be better off with a cordless drill/driver, impact driver, or hammer drill with this comprehensive guide.

If you're in the market for a power tool to tackle your upcoming DIY projects, you might find yourself standing in the power tool aisle of your local hardware store, wondering which tool is best suited for your specific project. While cordless drills and impact drivers may seem fairly similar, don't be mistaken – there are subtle differences geared towards different applications. If you're looking for a jack-of-all-trades drill that can handle a variety of tasks on your to-do list, a cordless drill/driver might be the right choice.

However, if you have a specific project in mind, learning how hammer drills and impact drivers differ from one another is crucial. Hammer drills are designed to bore through tough materials like concrete and masonry with their pulsating motion, while impact drivers use rotational force to drive screws quickly and efficiently without stripping them. Whether you need to drill holes into concrete or drive screws into wood without breaking a sweat, this guide places all of the information right at your fingertips so you can make an informed decision about which tool is best for your needs. So before you head out to buy a power tool for that next DIY project, keep in mind that choosing the right one can make all the difference!

Hammer Drill vs. Impact Driver: What Are They Used For?

Hammer drills and impact drivers are two of the most commonly used tools in the construction and woodworking industries. While both serve multiple purposes, hammer drills are specifically designed for drilling into hard materials such as concrete, masonry, and stone. On the other hand, impact drivers shine when it comes to driving screws and bolts into wood or metal surfaces.

1. Hammer drill uses

Hammer drills have a wide range of uses when it comes to drilling holes into different surfaces. One of the most common uses is drilling into masonry surfaces such as brick walls or basement concrete. This monotonous task can become much easier with a hammer drill, as the hammer function activated when drilling punches the bit forward, making short work of tough materials like concrete and brick tile. Hammer drills include a special feature that allows them to be used for slippery tile or glass backsplash by preventing cracking and breaking while drilling holes.

Additionally, hammer drills are great for attaching framing lumber or attaching handrails to concrete steps. They are also perfect for hanging TV wall mounts and shelves on garage floors, permanently fixing power tool stands, and attaching mechanical system brackets on concrete utility room floors. It's important to note that drilling into these types of materials with a hammer drill requires special masonry bits that can withstand the intense pressure and provide cleaner holes than regular bits.

2. Impact driver uses

Impact drivers are a small tool that is helpful for driving smaller fasteners at high speeds. They are perfect for driving smaller screws into thick wood without splitting thin wood, as they allow you to apply a lot of torque to the screw without stripping the head. Some common uses for impact drivers include hanging cabinets and other heavy objects, installing a deck ledger board with lag bolts, and driving screws in tight spots or inside cabinets.

However, impact drivers are not just limited to driving smaller screws. They are also great for driving longer heavy-duty screws quickly and efficiently. With their high torque output and quick action, impact drivers can make short work of even the toughest jobs. Whether you're working on a construction site or just doing some DIY around the house, an impact driver is an essential tool that can help you get the job done faster and more efficiently than ever before.

Frequently Asked Questions

What are the benefits of an impact driver?

Impact drivers provide more torque and power than traditional drills, making them ideal for driving screws and fasteners into tough materials like hardwoods or metal. They also reduce user fatigue by transferring the force of the impact to the tool rather than the user's arm.

Are all hammer drills cordless?

No, not all hammer drills are cordless. Some models require an electrical outlet to operate while others use rechargeable batteries for portability.

When should you use an impact driver vs. a hammer drill?

Use an impact driver for fastening screws and bolts, while a hammer drill is best for drilling into harder materials like concrete and masonry.

What are the uses of a cordless drill/driver?

A cordless drill/driver is a versatile tool used for drilling holes and driving screws into various materials such as wood, metal, and plastic. It can be used for DIY projects, home repairs, furniture assembly, and construction work.

What is the difference between a hammer drill and an impact driver?

A hammer drill is used for drilling holes in hard materials like concrete while an impact driver is used for driving screws and fasteners. The main difference between the two is their purpose, with the hammer drill being better suited for drilling and the impact driver for driving.

Featured Images: pexels.com